FEA

Finite Element Analysis

- Software we use

- Solidworks

- Codeware

- AutoCad

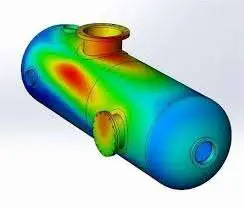

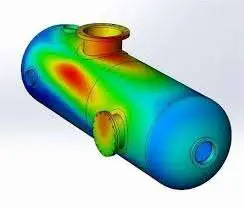

Finite Element Analysis (FEA)

Finite element analysis (FEA) is a computer-aided engineering (CAE) tool that uses calculations, models, and simulations to predict how an object will behave under various physical conditions. FEA is used to find vulnerabilities in design prototypes.

FEA is useful in structural, vibration, and thermal analysis. It has been widely implemented by automotive companies.

It is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.

J Lowry LLC can provide are a comprehensive resource to ensure compliance with the ASME code and to ensure that pressure vessels are designed and manufactured to meet the required safety standards.

Finite Element Analysis (FEA)

Finite element analysis (FEA) is a computer-aided engineering (CAE) tool that uses calculations, models, and simulations to predict how an object will behave under various physical conditions. FEA is used to find vulnerabilities in design prototypes.

FEA is useful in structural, vibration, and thermal analysis. It has been widely implemented by automotive companies.

FEA is a computerized method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects.

J Lowry LLC can provide are a comprehensive resource to ensure compliance with the ASME code and to ensure that pressure vessels are designed and manufactured to meet the required safety standards.

What type of problems can be solved using finite element analysis?

Finite element analysis (FEA) is an increasingly popular method used to solve problems in static structural analysis, dynamic analysis, vibration analysis, fluid flow, heat transfer, and many more types of physics.

The steps for an FEA are:

- Modeling

- Choosing the material of the structure

- Assembling the structure

- Choosing the solution method

- Creating boundary condition

- Choosing the element type

- Result

Calculations are run for every element or point of the mesh and then combined to make up the overall final result for the structure.

The results produced by FEA software are extremely detailed and accurate, offering a wide variety of conditions to test against. This is an advantage of finite element analysis over other methods, as it goes further to ensure the safety and efficiency of each product produced.

We have helped many companies take their first step in filling out the applications, all the way through the final step of demonstrating the ability to meet Code Standards at the Joint Review. We can tailor our services to meet your Code knowledge and can provide most all the written documentation you will need.

Office

Houston, TX

Proudly Serving the USA

For International Services, Please Contact Us

Contact Us

- Office Hours: M-F 8am-5pm, Closed S-S

- Phone: (281) 995-0552

- Email: info@jlowryllc.com