PRODUCTION DRAWINGS

- Software we use

- Solidworks

- Codeware

- AutoCad

Your Next Drawings Is Only A Click Away

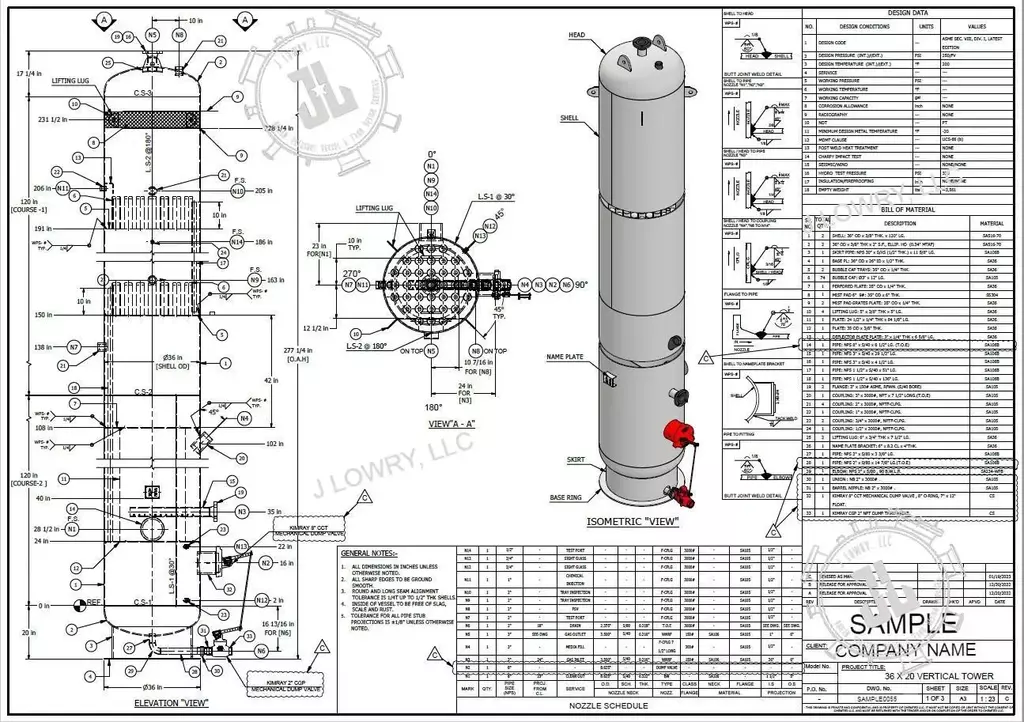

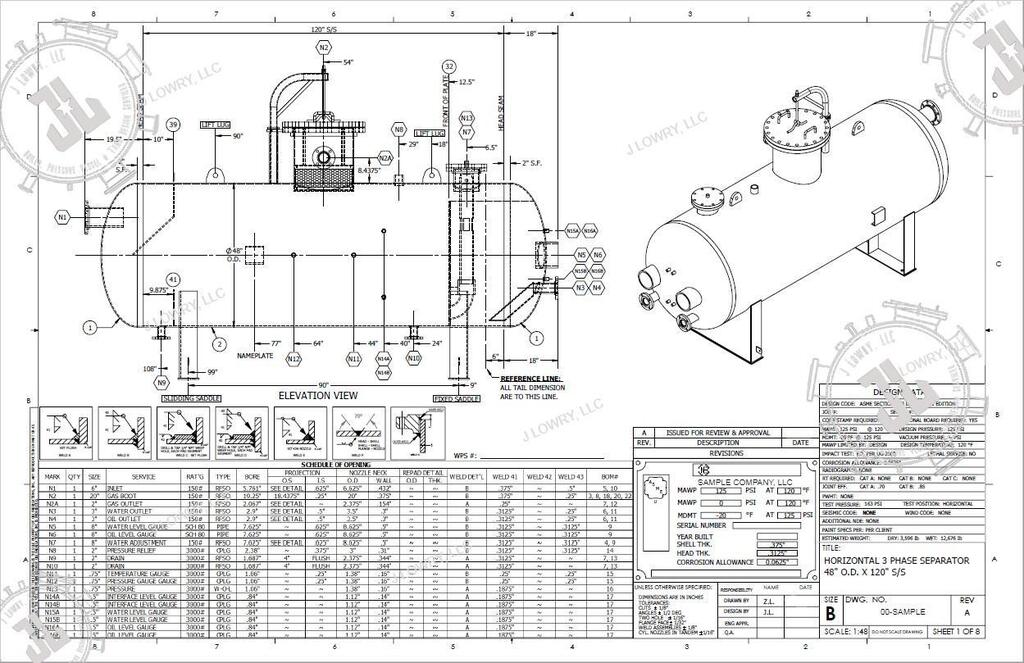

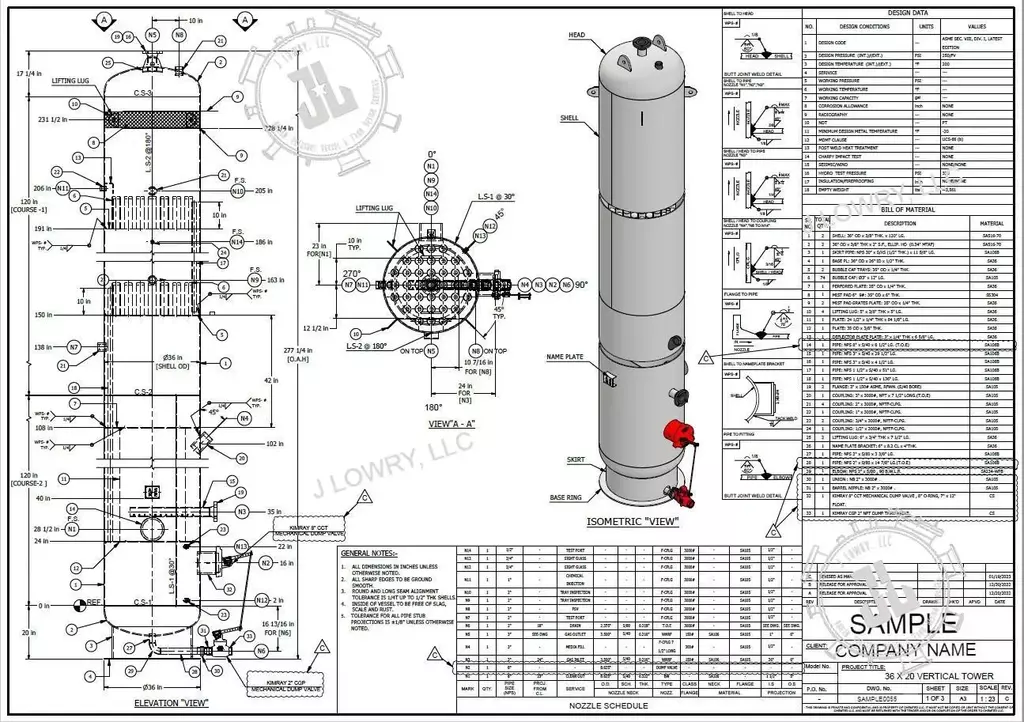

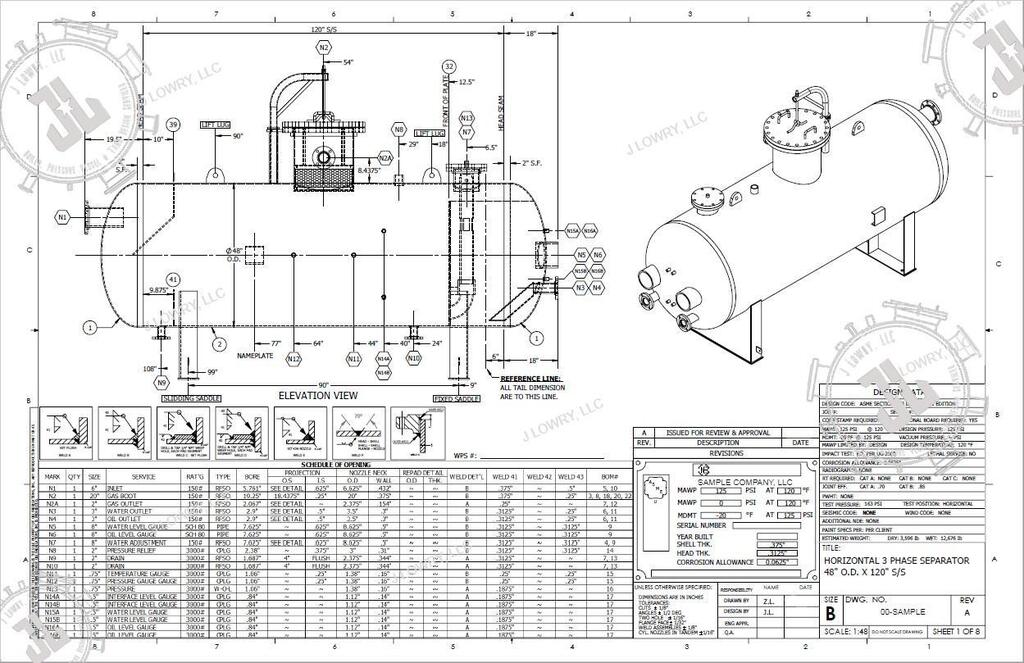

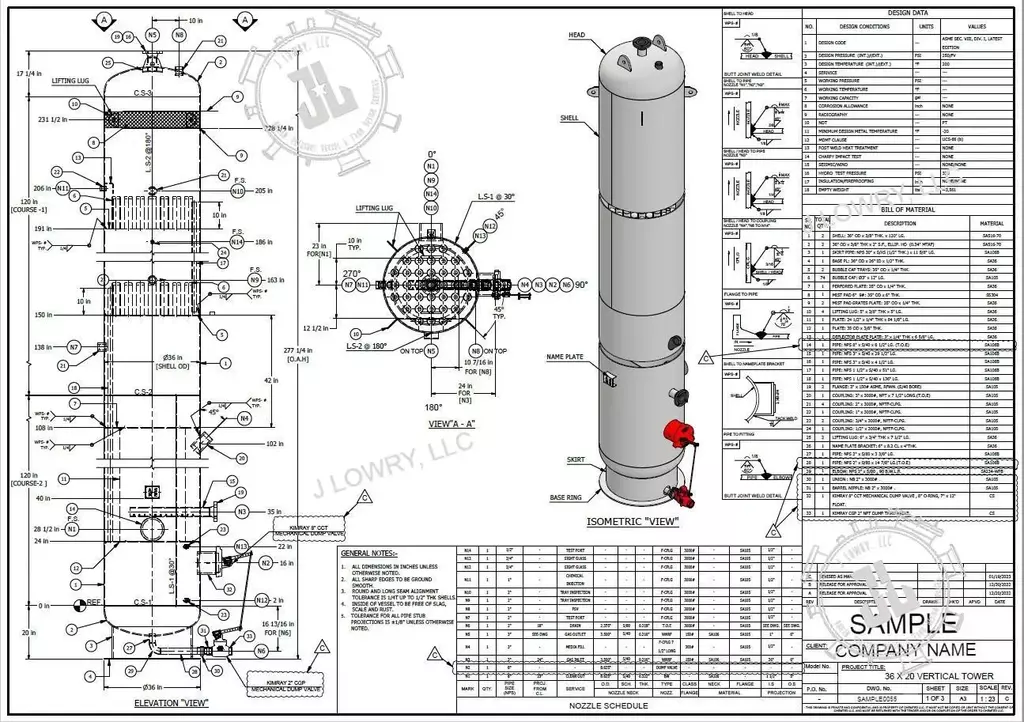

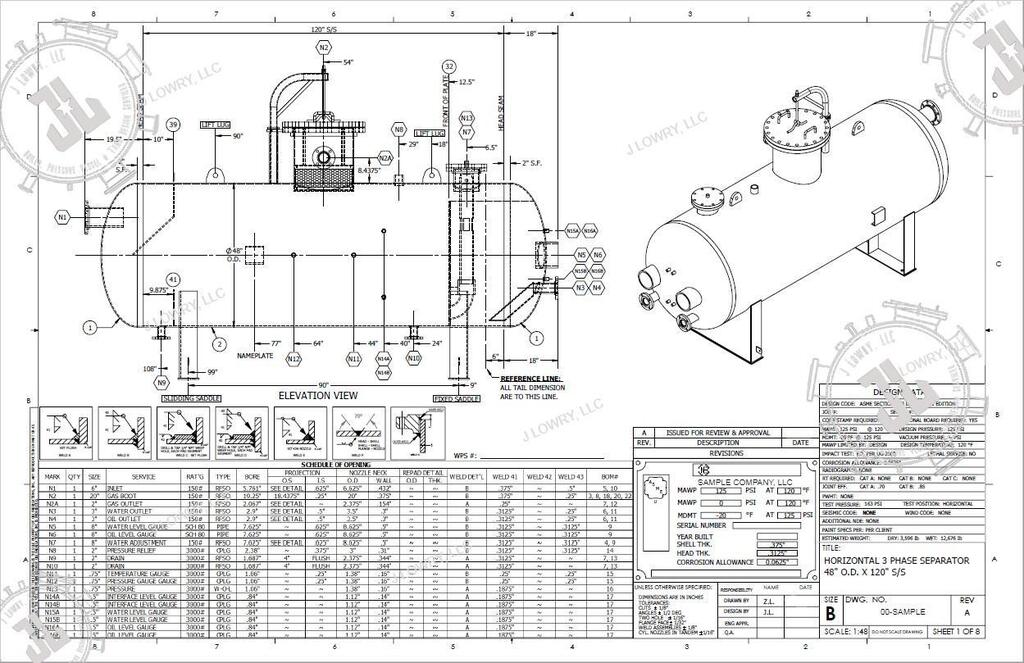

2-D AND 3-D ASME® Production Drawings

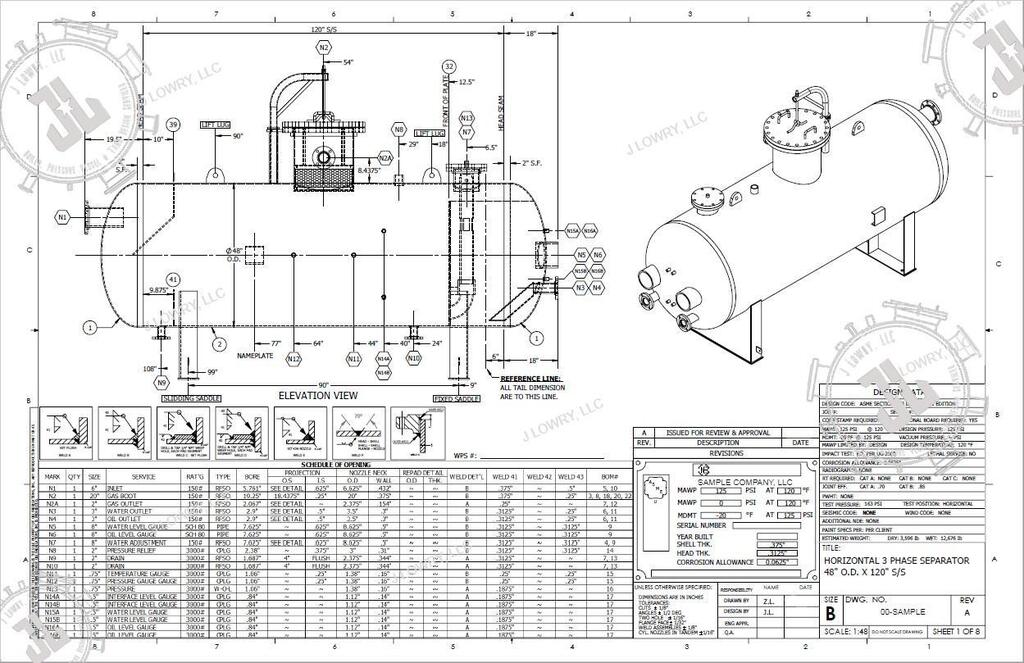

Whether you’re building your first “Demo” vessel, large Tray Towers, or anything in between, every aspect of the build is intricately detailed on our ASME® Production Drawings. This meticulous attention saves you time, money, and material by eliminating any confusion during construction. Here at J Lowry, LLC, we not only take pride in scrutinizing over the minor details, but we also go the extra mile to ensure your project goes off without a hitch.

Your Next Drawings Is Only A Click Away

One way we achieve this is by providing a detailed Bill of Materials on each ASME® Production Drawing. Consequently, your purchasing and receiving departments will find their jobs a breeze, enabling them to swiftly move materials to the shop floor where all the magic happens.

2-D AND 3-D ASME® Production Drawings

Whether you’re building your first “Demo” vessel, large Tray Towers, or anything in between, every aspect of the build is intricately detailed on our ASME® Production Drawings. This meticulous attention saves you time, money, and material by eliminating any confusion during construction. Here at J Lowry, LLC, we not only take pride in scrutinizing over the minor details, but we also go the extra mile to ensure your project goes off without a hitch.

One way we achieve this is by providing a detailed Bill of Materials on each ASME® Production Drawing. Consequently, your purchasing and receiving departments will find their jobs a breeze, enabling them to swiftly move materials to the shop floor where all the magic happens.

Your Next Drawings Is Only A Click Away

Our expert designers are dedicated to preparing high-quality 2D & 3D ASME® Production Drawings to guarantee top-notch results. These drawings are tailored to meet your specific requirements and are meticulously crafted in accordance with Code Standards. By employing our services, you can rest assured that your project will be handled with utmost professionalism and adherence to industry standards.

The level of proficiencies in the area of the ASME® Production Drawing is as follows

- General Preparation - To ensure a smooth fabrication process, we begin with meticulous planning and preparation.

- Arrangement & Details Drawings: We specialize in creating customized drawings that are tailored to suit your fabrication shop's requirements. These drawings cover all types of pressure vessels.

- Nozzles Drawings: Our team can provide detailed drawings specifically focusing on the design and arrangement of nozzles.

- General Arrangement and Detail Drawings: We offer drawings for platforms, ladders, and pipe supports that are carefully crafted to fit seamlessly into your fabrication shop.

- Internal Support Drawings: Our expertise extends to the design and development of internal support systems, including process trays, structural packing, pipe distributors, inlet/outlet devices, vortex breakers, support grids, mixing trays, hold-down gratings, mist pad supports, and more.

- Shell Development Drawings: We can provide detailed shell development drawings to verify the attachment of internals and externals, ensuring proper fouling prevention.

- Shipping Arrangement Drawings: Our team can create drawings that outline the optimal arrangement for shipping the fabricated components.

- Lifting Arrangement Drawings: We specialize in producing drawings that depict the proper lifting arrangements for safe and efficient handling of the fabricated structures.

- Bill of Materials: Alongside our drawings and calculations, we provide a comprehensive Bill of Materials in Excel format. This makes procurement and material management processes seamless.

- Additional Support for Structure: If required, we can provide detailed drawings for pipe racks, pipe supports, and skids structures, providing additional structural support and coordination.

- Providing additional support for structure for details drawings of Pipe rack, Pipe Supports, and Skids Structure

- Detailed Schedule of Nozzles: We can also provide a detailed schedule specifically focusing on the arrangement and specifications of nozzles.

Our current turnaround time is 10-12 business days

Don’t let the new regulation slow down your manufacturing while trying to understand the new regulations.

The 2021 edition of ASME® Section VIII, Division 1 has introduced requirements for the qualification of vessel designers. The introduction of Appendix 47 marks a foundational shift as this is the first time the mention of “certifying engineer” has appeared in the codebook.

We have a PIRC Appendix 47 program to help you become compliant! Don’t wait to contact us!

Let's get your Fabricators some Production Drawings

Get in touch with us today and let’s get started!

We offer services for USA, Mexico and Canada (CRN)

- Office Hours: M-F 8am-4:30pm, Closed S-S

- Phone: (281) 995-0552

- Email: info@jlowryllc.com

Is your company interested in obtaining your Code stamps for the fabrication of boilers, pressure vessels, or pressure piping components? We are here to help assist you.

We have helped many companies take their first step in filling out the applications, all the way through the final step of demonstrating the ability to meet Code Standards at the Joint Review. We can tailor our services to meet your Code knowledge and can provide most all the written documentation you will need.

Your Next Drawings Is Only A Click Away

2-D AND 3-D ASME® Production Drawings

Whether you’re building your first “Demo” vessel, large Tray Towers, or anything in between, every aspect of the build is intricately detailed on our ASME® Production Drawings. This meticulous attention saves you time, money, and material by eliminating any confusion during construction. Here at J Lowry, LLC, we not only take pride in scrutinizing over the minor details, but we also go the extra mile to ensure your project goes off without a hitch.

Your Next Drawings Is Only A Click Away

Here at J Lowry, we not only take pride in scrutinizing over the minor details, but we also go the extra mile to ensure your project goes off without a hitch.

With meticulous attention, our team provides a detailed Bill of Materials on each ASME® Production Drawings. Consequently, your purchasing and receiving departments will find their jobs a breeze, enabling them to swiftly move materials to the shop floor where all the magic happens.