Section VIII Division 1 Calculations

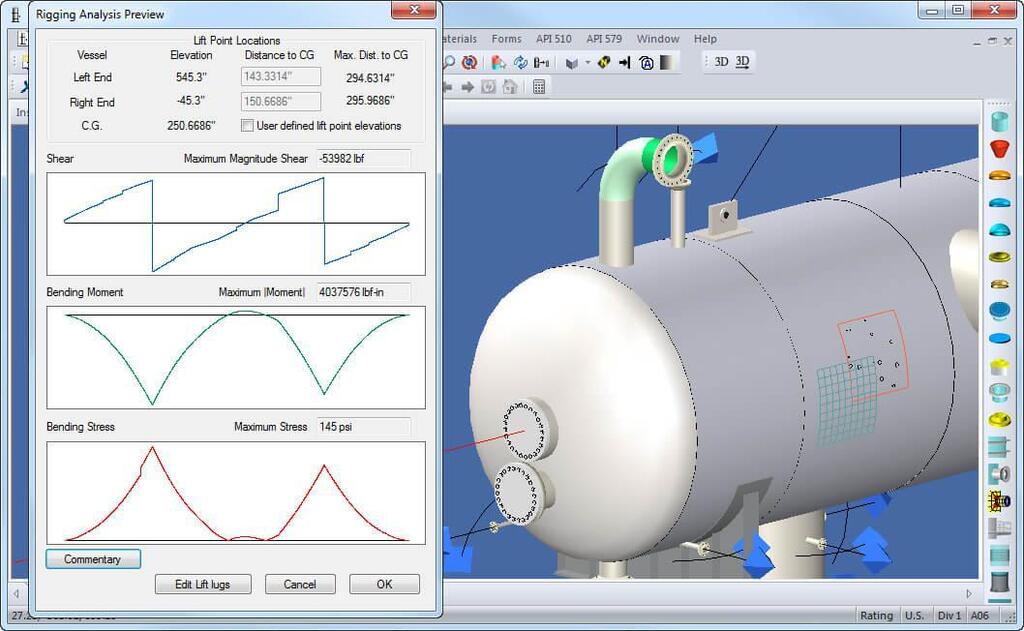

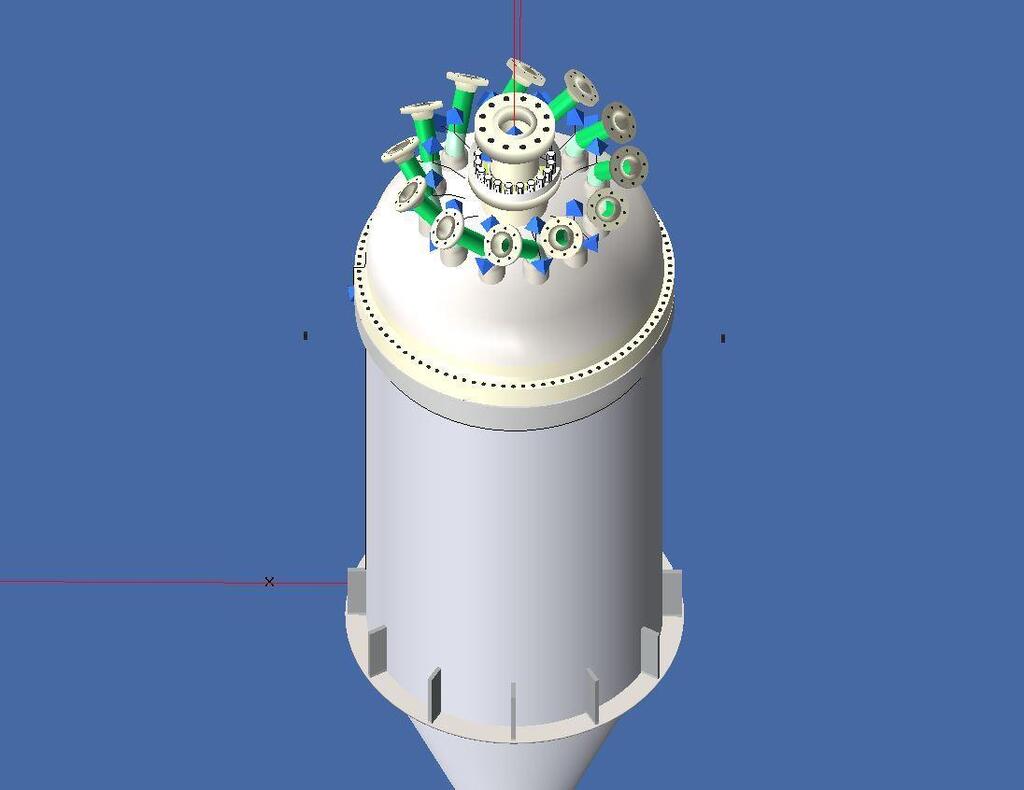

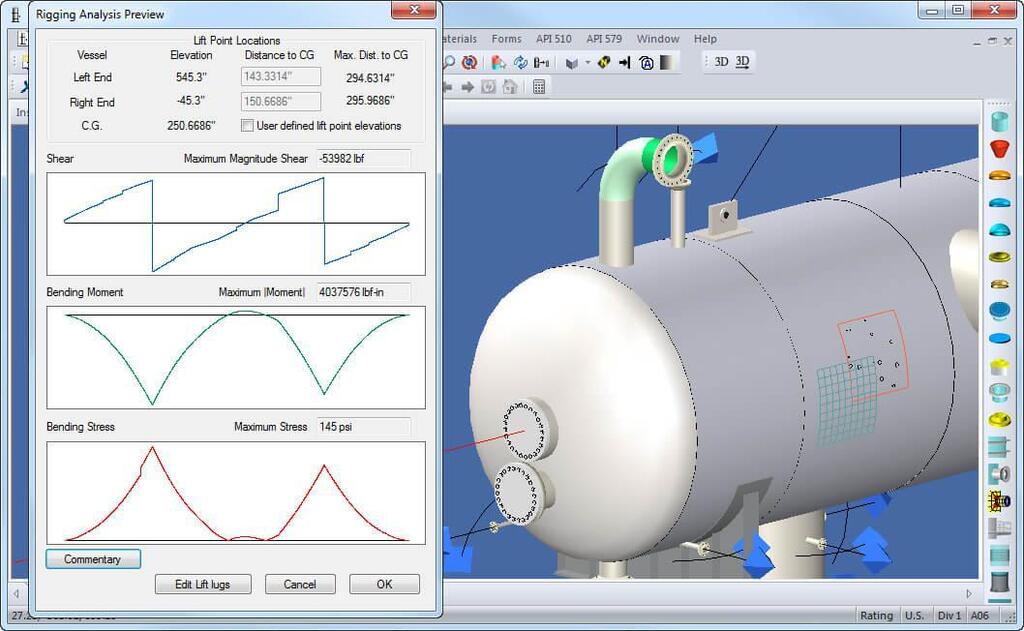

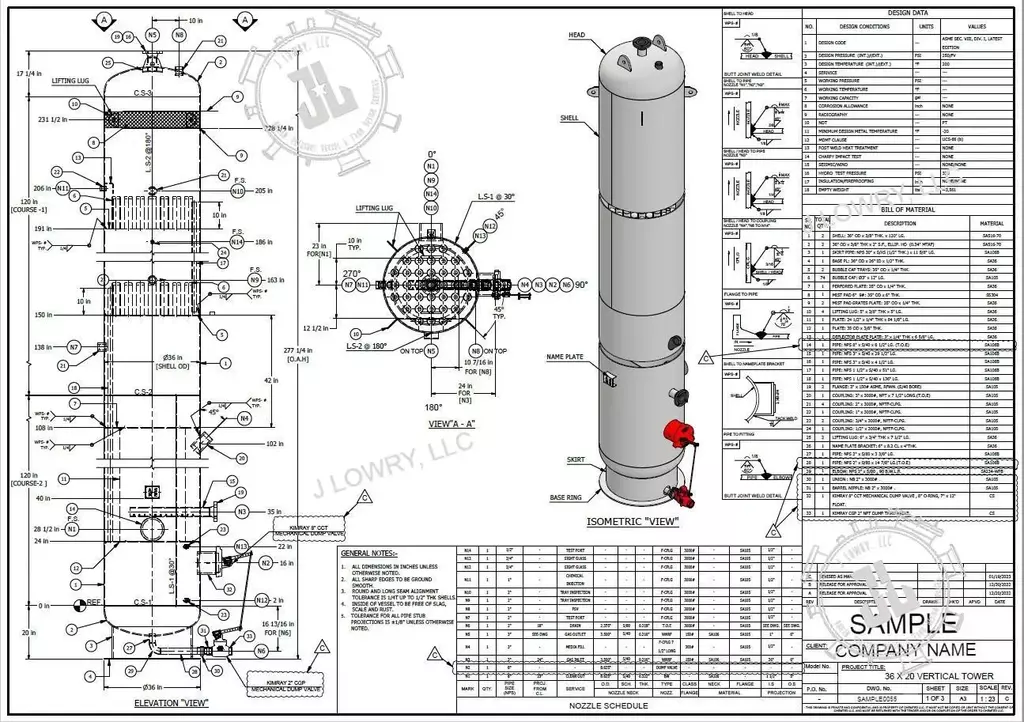

- Software we use

- Solidworks

- Codeware

- AutoCad

Section VIII Division 1 Calculations

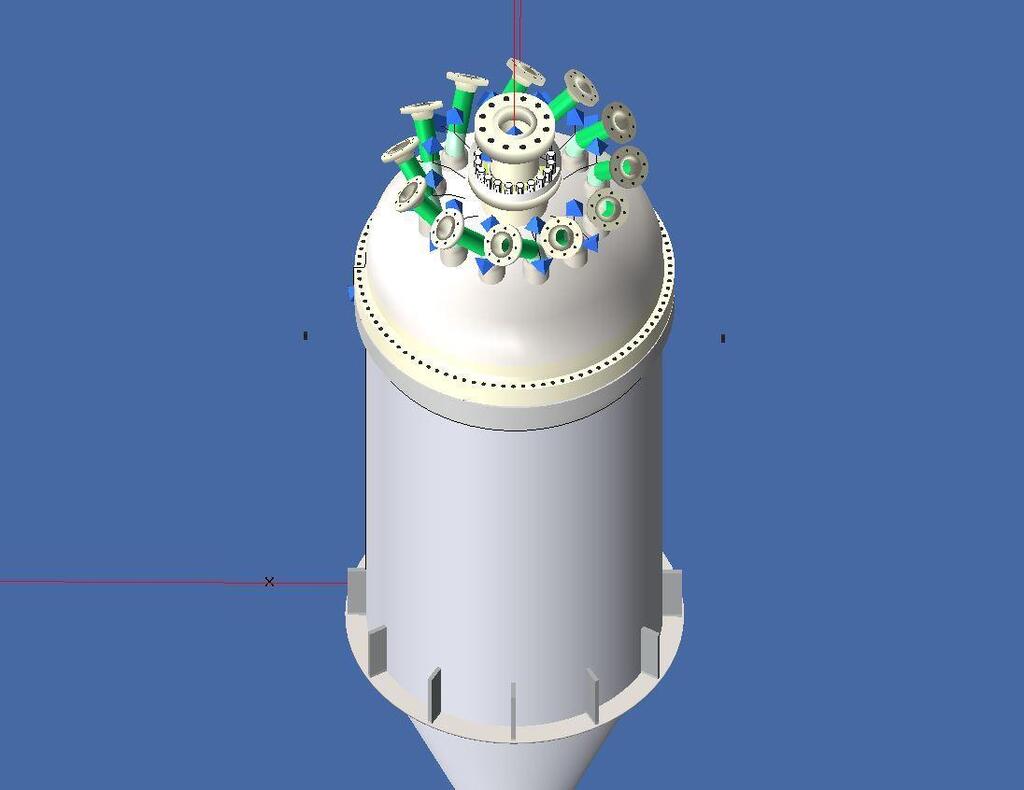

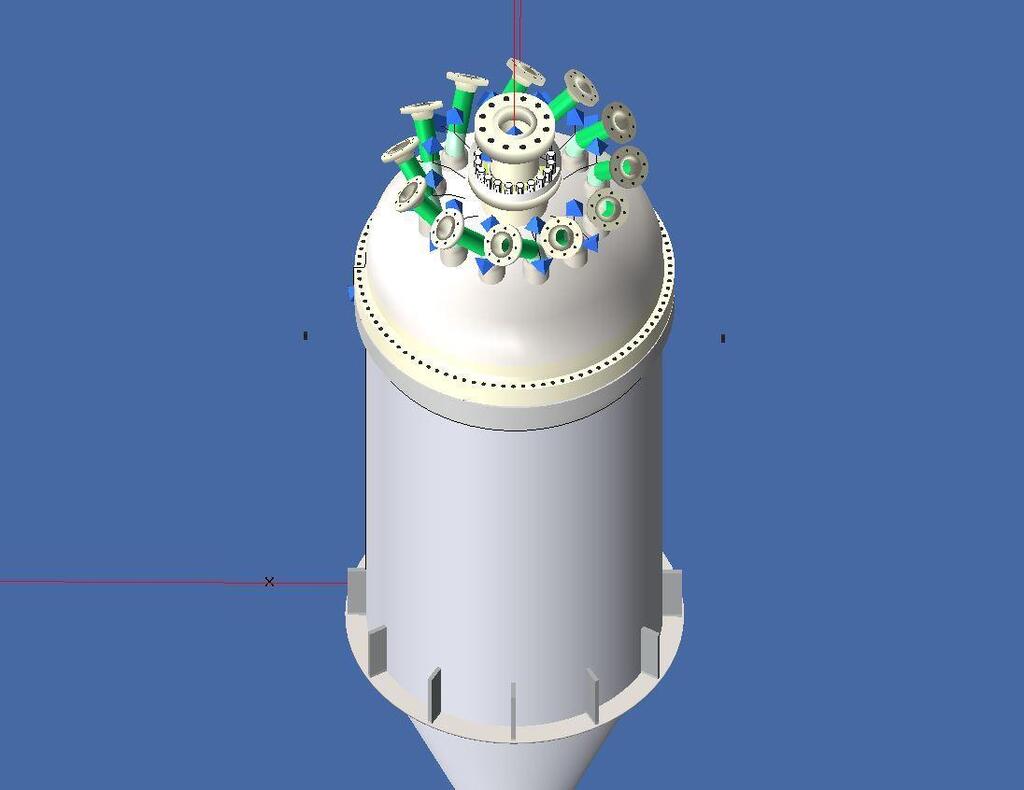

The Calculations J Lowry LLC can provide are a comprehensive resource to ensure compliance with the ASME code and to ensure that pressure vessels are designed and manufactured to meet the required safety standards.

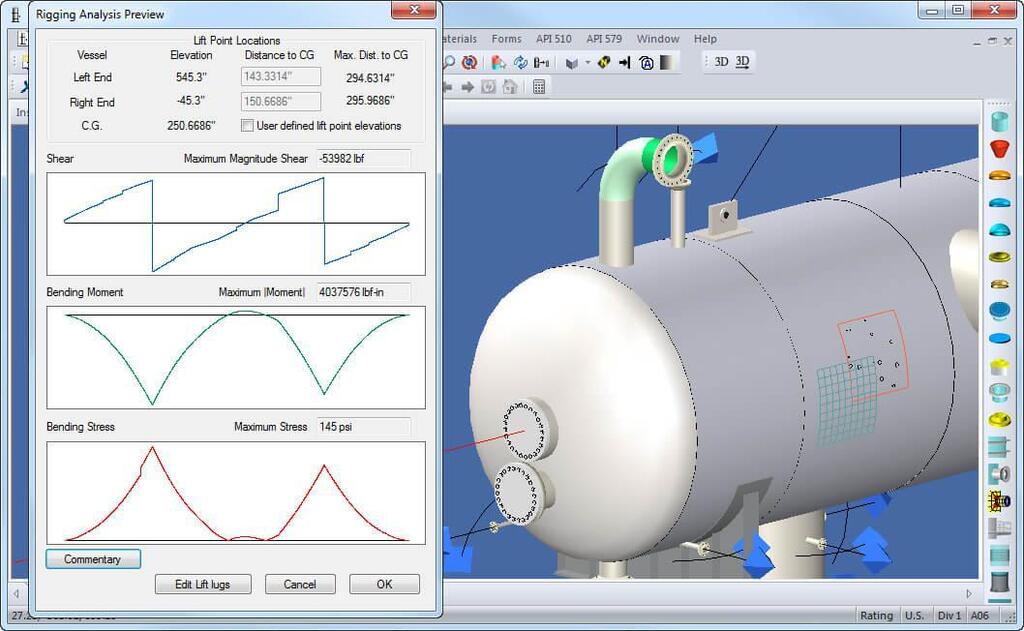

ASME® calculations, specified in Section VIII Division 1, are vital for ensuring the safety, reliability, and compliance of pressure vessel designs with industry standards. They consider factors such as internal/external pressures, temperature, material properties, and load conditions to determine dimensions and design features necessary for withstanding operating conditions.

Within Section VIII Division 1 Calculations section lies a critical part that outlines the methodology and formulas essential for designing pressure vessels. It encompasses various aspects, including:

- Determining allowable stresses for materials

- Calculating component thickness

- Assessing welded joint integrity

- Evaluating vessel structural stability under diverse operating conditions

Section VIII Division 1 specifically addresses the rules for the design and fabrication of pressure vessels that operate at pressures exceeding 15 psi (pounds per square inch) and have a maximum allowable working pressure (MAWP) exceeding 300 psi.

Section VIII Division 1 Calculations

ASME® calculations, specified in Section VIII Division 1, are vital for ensuring the safety, reliability, and compliance of pressure vessel designs with industry standards. They consider factors such as internal/external pressures, temperature, material properties, and load conditions to determine dimensions and design features necessary for withstanding operating conditions.

Within Section VIII Division 1 Calculations section lies a critical part that outlines the methodology and formulas essential for designing pressure vessels. It encompasses various aspects, including:

- Determining allowable stresses for materials

- Calculating component thickness

- Assessing welded joint integrity

- Evaluating vessel structural stability under diverse operating conditions

Section VIII Division 1 specifically addresses the rules for the design and fabrication of pressure vessels that operate at pressures exceeding 15 psi (pounds per square inch) and have a maximum allowable working pressure (MAWP) exceeding 300 psi.

Section VIII Division 1 Calculations

ASME® calculations, specified in Section VIII Division 1, are vital for ensuring the safety, reliability, and compliance of pressure vessel designs with industry standards. They consider factors such as internal/external pressures, temperature, material properties, and load conditions to determine dimensions and design features necessary for withstanding operating conditions.

Within Section VIII Division 1 Calculations section lies a critical part that outlines the methodology and formulas essential for designing pressure vessels. It encompasses various aspects, including:

- Determining allowable stresses for materials

- Calculating component thickness

- Assessing welded joint integrity

- Evaluating vessel structural stability under diverse operating conditions

Section VIII Division 1 specifically addresses the rules for the design and fabrication of pressure vessels that operate at pressures exceeding 15 psi (pounds per square inch) and have a maximum allowable working pressure (MAWP) exceeding 300 psi.

The Calculations J Lowry LLC can provide are a comprehensive resource to ensure compliance with the ASME code and to ensure that pressure vessels are designed and manufactured to meet the required safety standards.

We have a quick turnaround time and will not leave you waiting and stressed. Our current turnaround time is 10-12 business days.

Do you need a ASME® Production Drawing to accompany the Section VIII Division 1 Calculations?

There are many factors to worry about in designing a vessel, but Code Compliance should not be one.

With decades of hands-on industry experience and state-of-the-art design software, we can help trim the fat from any design so that you can rest assured that you are building the leanest and most cost-effective vessel possible.

We have a quick turnaround time and will not leave you waiting and stressed. Our current turnaround time is 10-12 business days.

Office

Houston, TX

Proudly Serving the USA

For International Services, Please Contact Us

Contact Us

- Office Hours: M-F 8am-5pm, Closed S-S

- Phone: (281) 995-0552

- Email: info@jlowryllc.com

Follow Us

With over 40 years of experience in the ASME Code and manufacturing experience, consulting can range from helping to understand parts of the Code to help with project start-up, welding, design, quality programs, In-House NDE Certification and much more.